Giải pháp tối ưu

Chất lượng đảm bảo

Đối tác uy tín

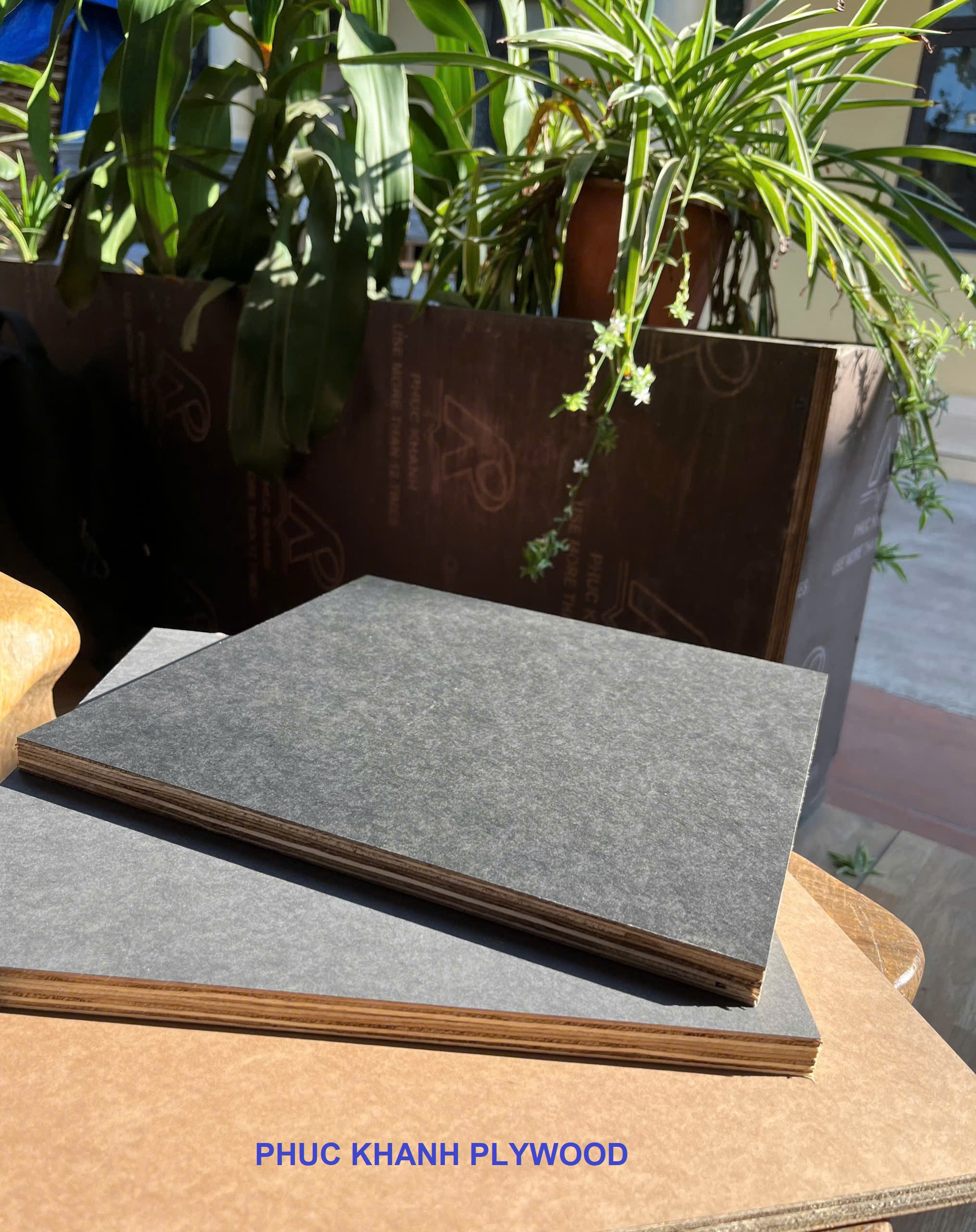

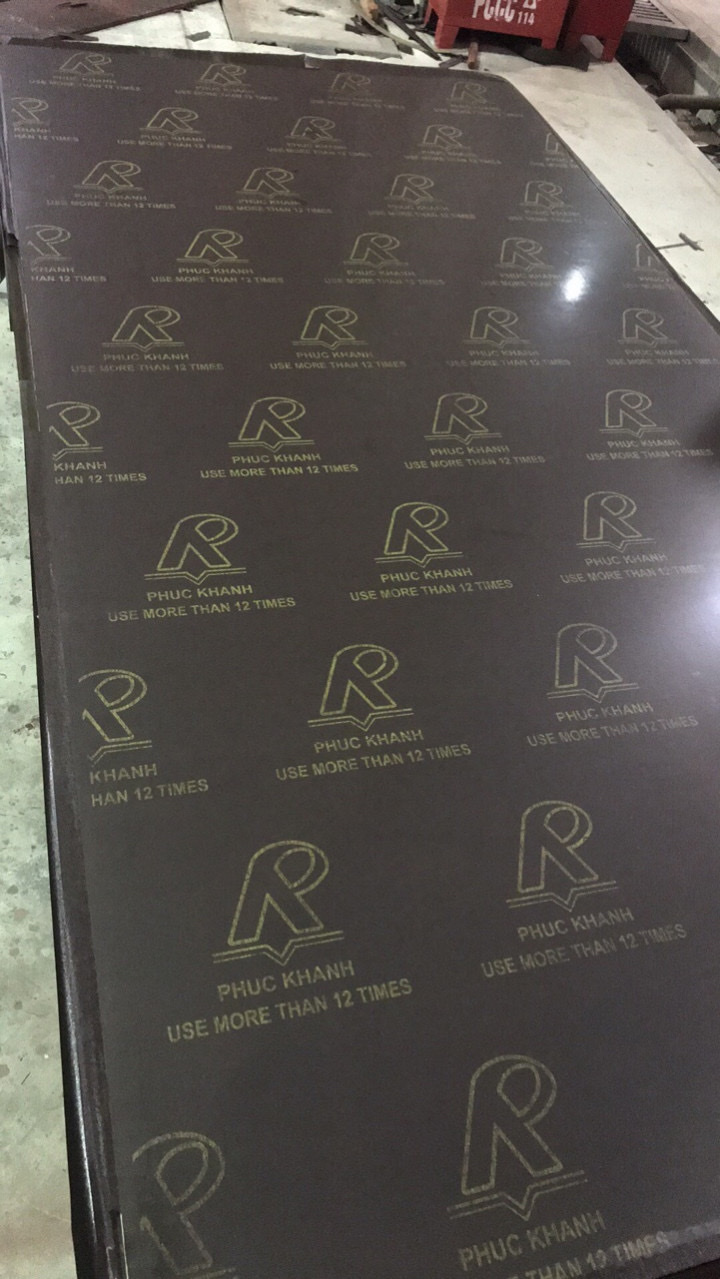

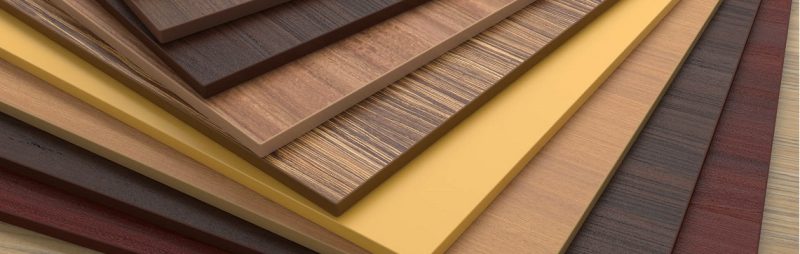

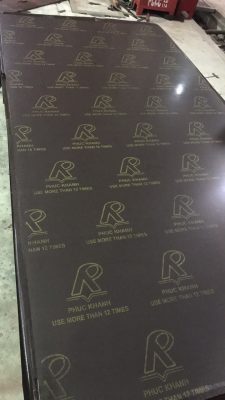

SẢN PHẨM TIÊU BIỂU

QUY TRÌNH SẢN XUẤT

01. LỌC VÁN

Ván được kiểm tra và phân loại loại ván, độ ẩm, chất lượng trước khi đưa vào tô keo

2. TÔ KEO

Keo được bôi đều lên bề mặt veneer bằng máy tô keo tự động

3. XẾP VÁN

Sau khi được phủ đều bằng keo chống nước, ván độn được sắp xếp thành từng lớp với vân gỗ của mỗi lớp hướng vuông góc với lớp trước.

4. ÉP NGUỘI

5. ÉP NÓNG

Ép nóng các tấm ván ép với nhiều lớp để cố định cấu trúc sản phẩm

6. BẢ MẶT

Bề mặt được kiểm tra và xử lý bằng một loại bột trét gỗ được pha chế đặc biệt.

7. CHÀ NHÁM

Bề mặt ván ép được chà nhám bằng máy chà nhám băng rộng để đạt được bề mặt nhẵn và đều. Bước này cải thiện chất lượng bề mặt, tăng cường liên kết cho lớp phủ và chuẩn bị tấm ván cho mục đích sử dụng cuối cùng.

8. CƯA CẠNH

Tấm ván ép được cắt chính xác theo kích thước tiêu chuẩn hoặc tùy chỉnh bằng cách sử dụng cưa có độ chính xác cao

9. ÉP MẶT

Ván ép được ép nhiều lớp với giấy film để đảm bảo dễ tháo ra và có thể sử dụng nhiều lần.

10. SƠN CẠNH

Các cạnh của tấm ván được bịt kín bằng bột trét gỗ và sau đó phun sơn để tăng khả năng chống ẩm và độ bền.

11. KIỂM TRA CHẤT LƯỢNG

Kiểm tra chất lượng Ván ép trải qua quá trình kiểm tra kỹ lưỡng về độ dày bề mặt, độ mịn và thử nghiệm bằng nước sôi. Bất kỳ miếng nào không đạt tiêu chuẩn đều bị loại

12. ĐÓNG KIỆN

Ván ép được đóng kiện và chuẩn bị để giao hàng

13. XUẤT HÀNG

14. DỊCH VỤ SAU XUẤT KHẨU

Chúng tôi duy trì kết nối với khách hàng sau khi giao hàng thông qua việc cung cấp chứng từ, hỗ trợ theo dõi lô hàng và xử lý các vấn đề phát sinh. Sự hài lòng của khách hàng là cam kết lâu dài của chúng tôi.

BÀI VIẾT MỚI NHẤT